Service Order Handling

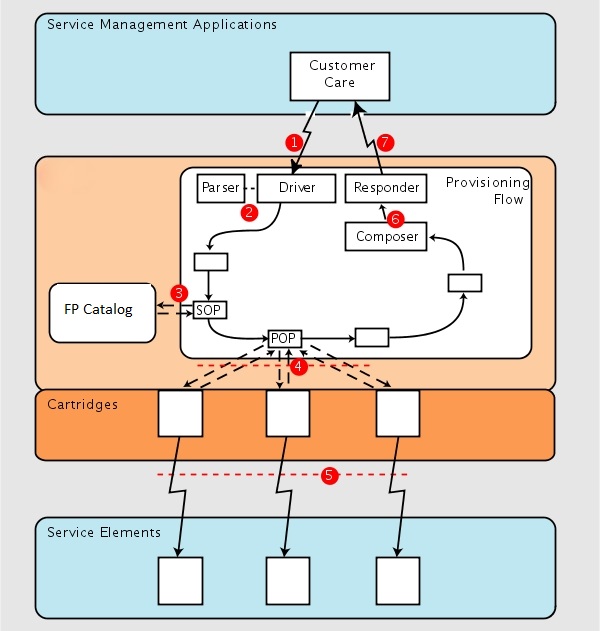

This section describes how a service order is handled in Fulfillment Provisioning. The example describes the complete process of provisioning a service order but does so generically, without details such as checkpoints, specific network elements, and so on.

The description on the numbered steps in the figure is as follows:

-

The customer care system sends an order message to Fulfillment Provisioning. For example, an EDIFACT message on a TCP/IP session.

-

The driver module receives the message and creates Fulfillment Provisioning service order. It parses the rest of the incoming message, creating product order objects and attaching them to the service order.

-

The Service Order Processor passes product orders to Fulfillment Provisioning Catalog. The catalog decomposes product orders into technical product orders. Subsequently, it attaches product order flows to specify work order sequencing. Fulfillment Provisioning Catalog also performs other processing such as, validating, enriching, and sequencing the order data. For each work order, Service Order Processor resolves routing (early routing).

-

The Product Order Processing (POP) module processes the sequenced, enriched technical product orders, and invokes work orders on cartridges. If a work order is not assigned to a cartridge, Product Order Processing resolves routing (late routing).

-

Cartridges translate the high-level work orders invoked by Product Order Processing into specific commands that provision and activate service elements.

-

The composer module builds a response message that initially sends the order to Fulfillment Provisioning. This message flows to the responder module.

- The customer care system receives the order response from the responder module.