Example 1.1: Designing and Analyzing a 2(7-4) Fractional Factorial Design

Box, Hunter, and Hunter (1978) report the results of a (hypothetical) experiment that nicely demonstrates how to design and analyze a fractional factorial design at two levels. Suppose a person is asked to cycle up a hill on consecutive days. The purpose of the study is to determine the effect of 7 different factors on the speed with which the person can climb the hill. These factors are:

- Seat position (up or down),

- Whether or not the dynamo is turned on,

- Position of the handlebars (up or down),

- Particular gear selection (low or medium),

- Whether or not the person is wearing a raincoat,

- Whether or not the person had breakfast in the morning, and

- Whether hard or soft tires are used on the bicycle.

The design for this study will first be generated and then the results will be analyzed.

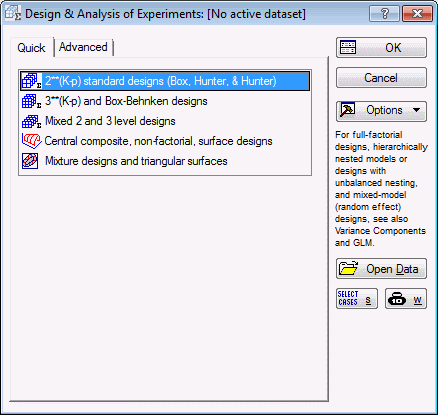

Ribbon bar. Select the Statistics tab, and in the Industrial Statistics group, click DOE to display the Design & Analysis of Experiments dialog box.

Classic menus. On the Statistics - Industrial Statistics & Six Sigma submenu, select Experimental Design (DOE) to display the Design & Analysis of Experiments dialog box.

Select 2**(K-p) standard designs (Box, Hunter, and Hunter).

Click the OK button to display the Design & Analysis of Experiments with Two-Level Factors dialog box.

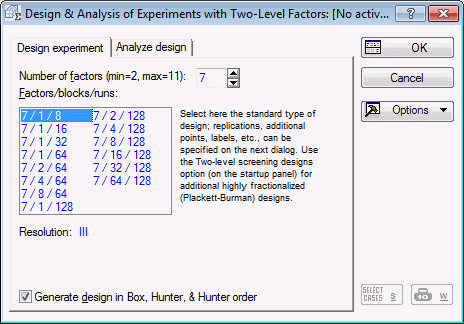

Select the Design experiment tab.

Enter 7 as the Number of factors, and select design 7/1/8 (7 factors, 1 block, 8 runs).

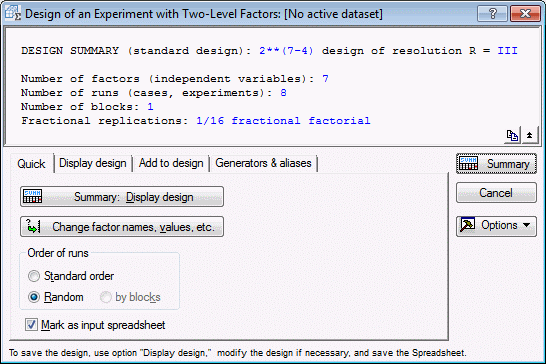

Examining the design. In the Design & Analysis of Experiments with Two-Level Factors dialog box, click the OK button to display the Design of an Experiment with Two-Level Factors dialog box, which contains numerous output options for reviewing the design.

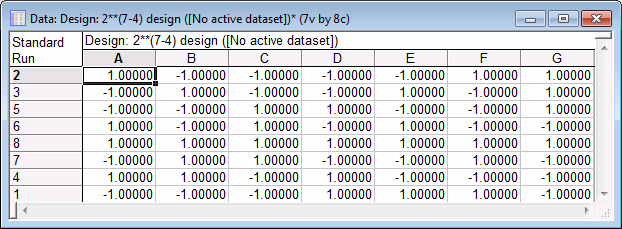

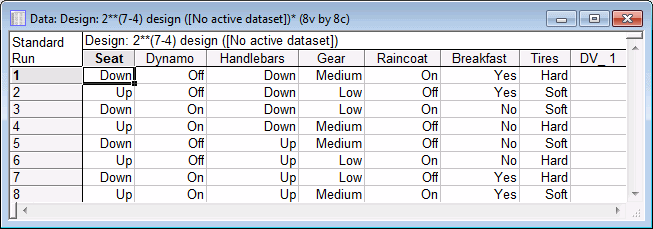

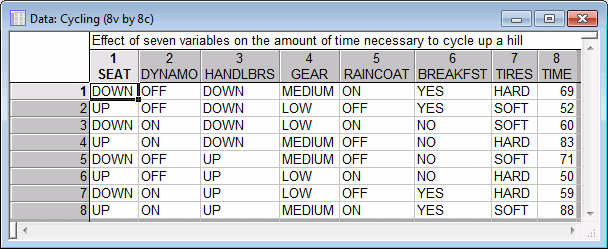

First, examine the runs in the design. For now, accept the default selections on the Quick tab, and click the Summary: Display design button to display a spreadsheet specifying the settings for each experimental run.

For example, if you are using two machines in your experiment and want to include a Machine factor in the design, that factor would be qualitative since you either use one machine or the other, and you cannot set this factor to a level in between. Alternatively, Seat Position, which is one of the factors in this example experiment, is a continuous variable, because the height of the seat position can be varied continuously between the up and down positions.

Continuous factors are indicated in the spreadsheet by the notation (Cont.) in the column heading if letters or numbers are used instead of factor names.

Categorical variables cannot be set at their center levels and, thus, for every center point requested via the center points option in the Design of an Experiment with Two-Level Factors dialog box, Statistica will construct a full factorial design for the categorical variables in the design.

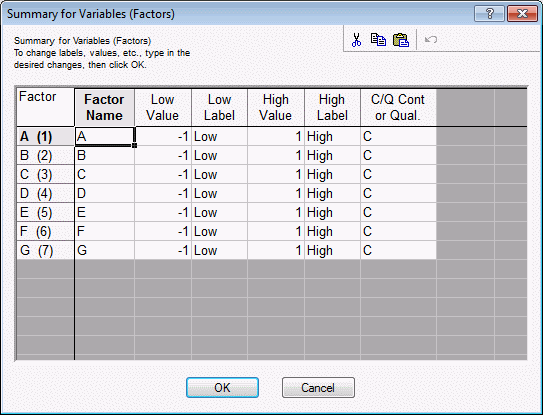

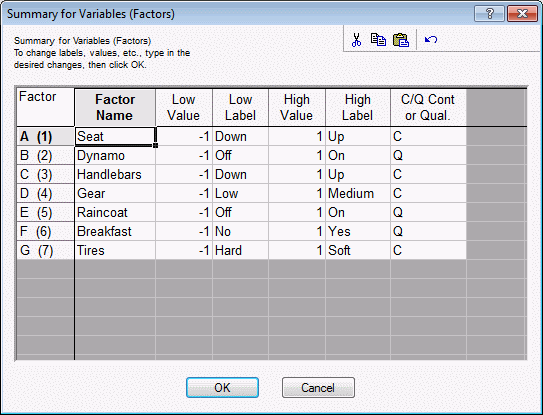

Customizing the default design, saving the design. Return to the Design of an Experiment with Two-Level Factor dialog box, and click the Change factor names, values, etc. button to display the Summary for Variables (Factors) dialog box.

This dialog box not only displays the factor names, highs and lows, etc., but you can also modify the values. For example, enter the following values:

You have now given the factors and the factor settings more meaningful names. For this example, the actual low and high values were not changed. If you exit this dialog box by clicking the OK button, all specifications entered here will be read by Statistica (and will be used in subsequent spreadsheets). If you close the dialog box in any other way, the changes will be discarded.

Now, click the OK button to return to the Design of an Experiment with Two-Level Factor dialog box.

Randomization of runs assures that all such systematic influences affect the experiment in a random (non-systematic) manner and, thus, that they will hopefully "even out" in different experimental runs.

For this example, however, select the Standard order option button.

In the Order of runs group box, select the Standard order option button.

In the Show (in Spreadsheet) group box, select the Text labels option button.

Now, click on the Quick tab and click the Summary: Display design button to produce the spreadsheet.

Ribbon bar. On the Home tab, click Save.

Classic menus. On the File menu, select Save.

Reviewing the design characteristics.

Reviewing design generators. As discussed in the Introductory Overview, 2(k-p) fractional factorial designs "sacrifice" interactions to allow main effects to be estimated with fewer runs than would be required by a full factorial. Without going into the details of this procedure, the logic of it is as follows (see Box and Draper, 1987; Box, Hunter, and Hunter, 1978; Mason, Gunst, and Hess, 1989; or Ryan, 1989).

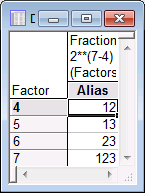

First, you take the full factorial that can be constructed based on the respective number of runs; in this case, 8 runs can accommodate a 3-factor complete factorial design. Next, the program "sacrifices" the highest-order interactions in that design to "create" new factors (main effects). This process is summarized in the notation that is used to refer to fractional designs: In this example, you have a 2(7-4) design. This means that you have seven factors overall, four of which were created as aliases of interactions. To see which interactions were sacrificed, review the design generators by clicking on the Generators & aliases tab and clicking the Generators of fractional design button.

It turns out that factor 4 was created from the interaction of factor 1 by 2; factor 5 was created from the interaction of factor 1 by 3; and so on.

In the current example, R is equal to 3; therefore, no l=1 level interactions (i.e., main effects) are confounded with any other interaction of order less than R-l=3-1=2. Thus, the main effects in this design are confounded with the two-way interactions.

Close the analysis and all related spreadsheets.

Ribbon bar. Select the Home tab. In the File group, on the Open menu, select Open Examples to display the Open a Statistica Data File dialog. Double-click the Datasets folder, and then open the data set.

Classic menus. On the File menu, select Open Examples to display the Open a Statistica Data File dialog. The data file is located in the Datasets folder.

Specifying the design. Start the Experimental Design (DOE) analysis:

Ribbon bar. Select the Statistics tab, and in the Industrial Statistics group, click DOE to display the Design & Analysis of Experiments Startup Panel.

Classic menus. On the Statistics - Industrial Statistics & Six Sigma submenu, select Experimental Design (DOE) to display the Design & Analysis of Experiments Startup Panel.

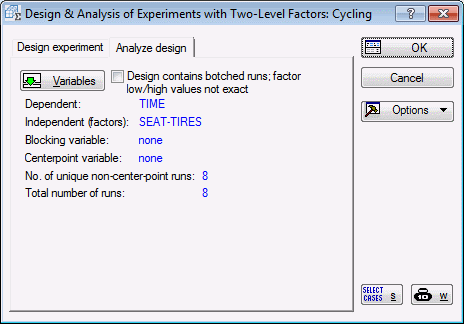

Select 2**(k-p) standard designs (Box, Hunter, and Hunter), and click the OK button. In the Design & Analysis of Experiments with Two-Level Factors dialog box, click on the Analyze design tab. Click the Variables button to select the Dependent and Indep. (factors). The dependent variable in this case is variable Time, which contains the times that the person required to cycle up the hill; variables Seat through Tires are the independent variables because they contain the codes (+1,-1) that uniquely identify to which group in the design the respective case belongs. After selecting the variables, click the OK button. The Design & Analysis of Experiments with Two-Level Factors dialog box will look like this.

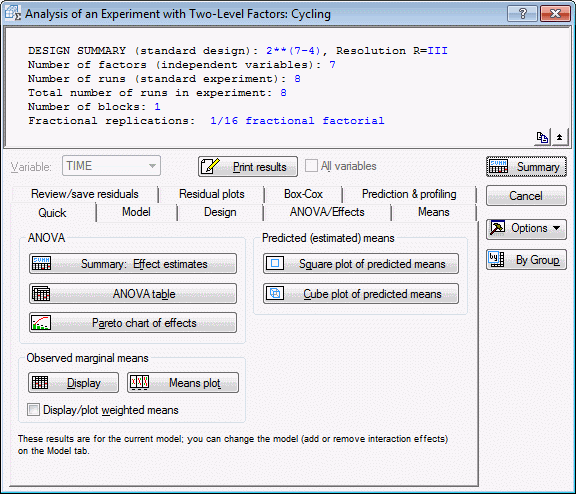

Some of the options available in this dialog box are the same as the options in the dialog box resulting from generating a design. Thus, on the Design tab, you could display the design, review the aliases, etc. Some of the new options are described below.

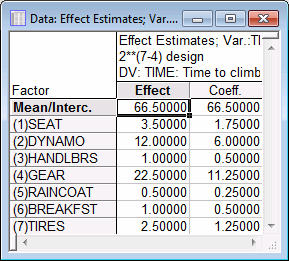

By default, Statistica fits a simple main effects model without interactions. [Remember that the design is of resolution III (3); hence, the two-way interactions are confounded with the main effects, and they cannot be estimated from this design.] The first numeric column of the spreadsheet shown above contains the Effect estimates. These parameter estimates can be interpreted as deviations of the mean of the negative settings from the mean of the positive settings for the respective factors. So, for example, when the seat position went from down (-1) to up (+1), the time to climb the hill increased by an average of 3.5 seconds.

The second numeric column contains the effect Coefficients. These are the coefficients that could be used for the prediction of climb-time for new factor settings via the linear equation:

ypred. = b0 + b1*x1 + ... + b7*x7

where ypred. stands for the predicted climb-time, x1 through x7 stand for the settings of the factors (1 through 7), b1 through b7 are the respective coefficients, and b0 stands for the intercept or mean.

Note that, for this design, the spreadsheet of effect estimates does not show the standard errors for the parameters or tests of Statistical significance. This is because this is a saturated design, where all degrees of freedom (i.e., information) are used to estimate the parameters, and no independent assessment of the error variance is available.

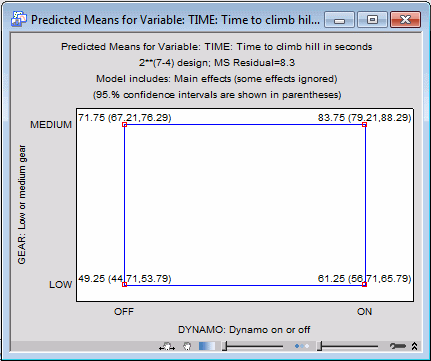

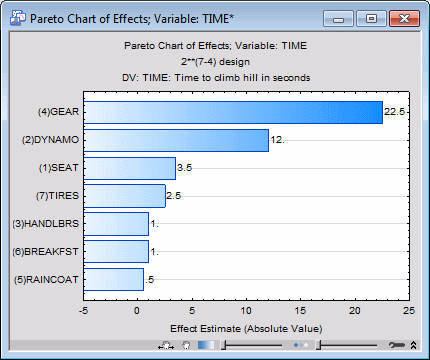

To summarize the results so far, it appears that the gear selection (low is better, that is, leads to shorter climbing time) and the dynamo setting (off is better) had the largest impact on the person's speed when cycling up the hill.

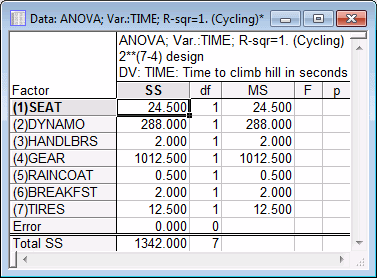

As you can see, in this example there are no degrees of freedom remaining for the Error. Put another way, all of the information in the data was used up to estimate the factor effects (sums of squares).

Again, the largest proportion of variance in the person's climbing time can be explained by the Gear factor; the Dynamo factor explains only about a quarter as much of the variability, and the remaining factors seem rather insignificant.

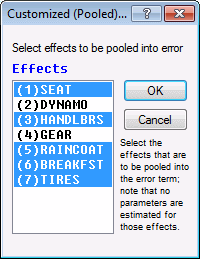

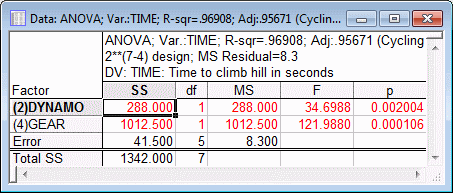

Click OK, and then return to the ANOVA/Effects tab. Click the ANOVA table button to display the ANOVA table again.

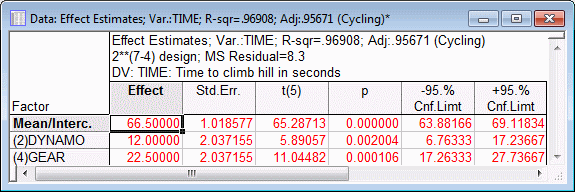

Now only the two factors Dynamo and Gear are included and tested for Statistical significance against the residual or Error variability. In this particular case, we should be careful not to interpret the p values too literally. Those values assume that we hypothesized a priori, that the two factors Dynamo and Gear would be the only important factors in the experiment; however, we made this determination after looking at the results, that is, post hoc. To use a "loose" metaphor, it is as if we predicted the winning lottery numbers after we read the numbers in the paper; clearly we can do much better than what would be expected by pure chance. Nevertheless, it is instructive to see the F-ratios, which, as usual, are the ratios of the respective mean-square-effect and the mean-square-error. Statistica can also construct confidence intervals for the ANOVA parameter estimates based on the pooled estimate of error.

Return to the ANOVA/Effects tab, and click the Summary: Effect estimates button again.

Select the Quick tab.

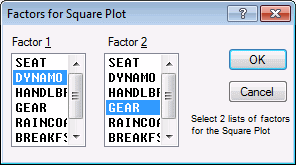

Since there are two factors that seem to be most important in this study, click the Square plot of predicted means button in the Predicted (estimated) means group box. In the Factors for Square Plot dialog box, select the two factors Dynamo and Gear,

and then click OK.

This plot shows the predicted means for the low and high settings for the two factors when all other factors are at their respective mean (i.e., 0 in coded form). Also included are the confidence intervals for the predicted means, based on the pooled error term.

To produce this plot for all main effects, select the Model tab and clear the Ignore some effects check box in the Include in model group box.

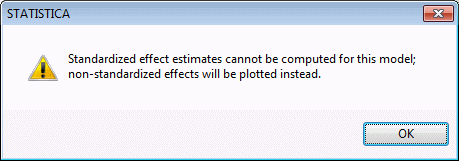

Then, select the Quick tab, and click the Pareto chart of effects button. A message will be displayed informing you that the default plot for standardized effects cannot be produced because, as discussed earlier in this example, when all effects are estimated there are no degrees of freedom left to estimate the error variability.

Disregard the message (click OK) to produce the plot of the non-standardized effects.

This graph will show the ANOVA effect estimates plotted against the horizontal axis. If there is an estimate of error variability available, this plot (for standardized effects) will also include a vertical line to indicate the p=.05 threshold for Statistical significance (see Example 1.2). This plot is particularly useful for presenting the results of experiments to laymen who are not familiar with the interpretation of numerical results from ANOVA.

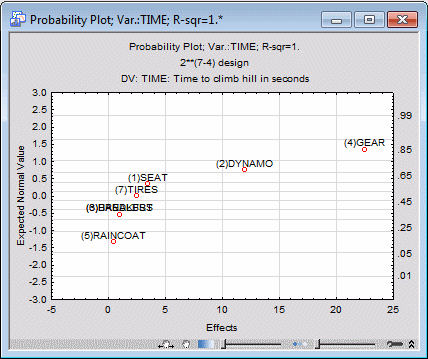

Select the ANOVA/Effects tab. Before producing the plot, ensure that the Label points in normal plot check box is selected. Then, click the Normal probability plot button in the Plots of effects group box.

This plot is constructed as follows. First, the effect estimates are rank ordered. From these ranks, z values (i.e., standard values of the normal distribution) can be computed based on the assumption that the estimates come from a normal distribution with a common mean. These z values are plotted on the left-Y axis in the plot, and the corresponding normal probabilities are shown on the right-Y axis in the plot. If the actual estimates (plotted on the X-axis) are normally distributed, all values should fall onto a straight line in the plot. This plot is very useful for separating random noise from "real" effects. The estimates for effects that are actually zero in the population will assume a normal distribution around a common mean of zero; effects that "truly exist" will be shown in this plot as outliers.

In the plot above, again the points (marked in the plot) for the Gear and Dynamo main effect appear different from the other effects.

Summary. We conclude from this study that the most significant factor affecting a person's speed when cycling up a hill is the proper gear selection. There also is an indication that the dynamo setting has an effect, although that effect is not nearly as strong.

See also, Experimental Design Index.