Gage Repeatability & Reproducibility Results - Gage Performance Tab

Select the

Gage performance tab of the

Gage Repeatability & Reproducibility Results

Use the options on this tab to compute gage performance curves, and estimate (display) the misclassification risk given your 1) measurement system and 2) upper and lower specification limits (beyond which a part or item would be rejected). The computations on this tab are also described in the ASQC/AIAG Measurement Systems Reference Manual (2002).

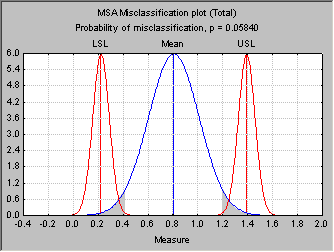

The graph shows a normal distribution centered over the respective mean for this study. The standard deviation of this curve is determined either from the Total variability, or the Part-to-Part variability (as indicated at the top of the graph).

The two normal curves over the Lower specification limit and the Upper specification limit (LSL and USL respectively) represent the measurement variability (combined R&R) around these limits. The grey area indicates the reasonable risk that an item will be erroneously misclassified as acceptable (inside the USL-LSL range), when in fact it is not, i.e., when the item actually came from a distribution centered over the respective limit (LSL, USL), and specifically, falls within the area defined by ±3 time sigma (measurement variability) around the respective limit. That probability is reported at the top of the chart.